Part 1 of this article covers the basic parts list, code, and assembly.

UPDATE (January 2023): I’ve built a version 2.0 of this prop. See “Enchanted Rose 2.0: Raspberry Pi Prop with Falling Petals” for updated instructions.

UPDATE (April 2021): The Bluetooth shield used in this Arduino-based project is apparently discontinued. If I were to build this project again today, I’d make it a Raspberry Pi Zero W with Headers (or 3B+) based device. Take note on that order page of the adapter cables and power supply you should also get.

The RPi would run a simple Flask (python) server to control the servo motors. I’d attach an Adafruit Servo Motor HAT to do the servo motor control, and then build a simple web application to control the prop. This would eliminate all the Swift Coding involved in the app controller, and allow for much easier building/debugging. I would absolutely use the same drop mechanism. That is, servo motors, spring loaded magnets mounted in a wooden golf-ball sized drawer handle.

To be clear, this updated approach would mean I would not order the Redbear Labs BLE shield nor the Arduino, nor would I futz with the fun but unnecessary iOS app. But nothing prevents you from building a nice one to control a Raspberry Pi based prop!

Now that the Enchanted Rose Prop is nearing completion, I wanted to cover a few final details. Here’s a video of the app and prop in its current form:

Aesthetic Touchup

Some paint and floral tape was used to give the stem a little more rose-like appearance. Still in progress, but you get the idea.

Ring Lights

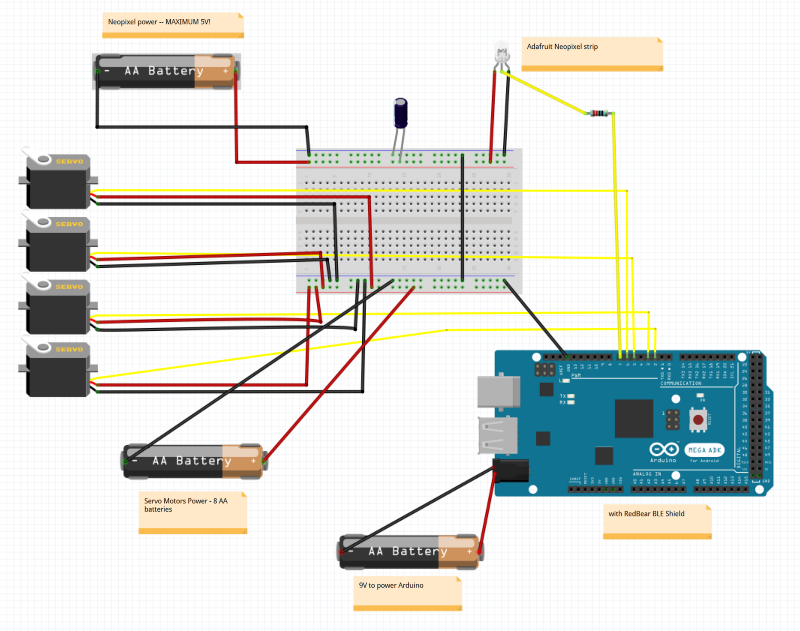

The ring lights are a Neopixel 1 meter long strip. I cut the strip between the LEDs at roughly the 40 LED mark. Doing so has no effect on the Neopixel, as long as you cut between LEDs.

Big gotcha: These lights only want 5V maximum! I fried the first set by overpowering it. Don’t make that mistake — it’s irreversible.

Stem Accent Lights

I purchased a cheap set of LED lights to add some interest to the stem.

These are powered by their own 3-AA battery pack. I’m sure I could use the same 3 AA-battery pack used by the Neopixel strip, but after frying one of those strips, I chose not to risk wasting another $30 tempting fate. To turn these on and off, an N-channel MOSFET transistor is used, with its gate actuator tied to pin 10 of the Arduino.

Basically, the MOSFET transistor lets current pass through if voltage is applied to the Gate pin (pin 1 in the diagram above.) When voltage on the gate goes LOW, the LED accent lights turn off. When voltage on the gate goes HIGH, the accent lights turn on.

Soundproofing

The servo motors are a little squeaky when moving. I installed some foam sound barriers (ordinary shipping packaging) to help dampen the sound.

Drop Mechanism

The initial approach of using piano wire to move flexible wires up and down worked fine from a dropping standpoint, but it had two distinct disadvantages in practice:

- the vertical extension above the bud made it hard to get the upper petals to to look real

- the “re-set” procedure was going to be way too hard for young adults to do Did I mention that after I had the prop working for an adult, my wife told me that the crew would be entirely comprised of fifth graders? “Hardening” the prop for fifth grade use for 8 performances in ways such as this was actually the most time-consuming part of the project.

So instead, I revised the attach/drop mechanism, to fishing-line-pulls-a-magnet.

I drilled four holes into a wooden 1 1/2″ golf-ball. Tip: use two drill bits, a small one that goes all the way through (just for the fishing line), and a wider one for the hole where the spring mechanism sits. You’ll want to give the spring something to push against, so don’t go all the way through the wooden ball with the drill, as I mistakenly did.

The key part are rod magnets which are inserted into thread covers and put into a spring:

I later added rubber caps over these magnets (but first drilled a small 6mm hole in the center.) I then hot-glued these caps-with-holes over these magnets. In “normal” state, the magnet protrudes through the caps to make surface contact with the washers inside the petals. When the Servo motor moves, it temporarily (2-3 seconds, programmable delay) pulls the fishing line which separates the magnet from the petal, and then resets it to the normal position. The advantage of this design is that it only uses servo motor power during the drop operation.

Result: TOTAL SUCCESS. Worked flawlessly in production and could even be re-set by kids (though I admit I double-checked pre-show.)

The fishing line is pushed through the (orange) nylon thread cover and a double knot is used to prevent it from pulling through. Then, the rod magnet is inserted, finally that’s inserted into a spring. That subassembly is repeated three more times, and inserted into the four holes in the wooden “bud.” You’ll want to make the exit hole for the fishing line quite a bit smaller than the upper hole, so the springs have something to push against. The only thing that comes through the bottom of that wooden ball is four strands of fishing line, which are fed down into the stem, one to each of the four servos.

The petals have a small metal washer hot-glued to the base, which is magnetically attached to the bud. When the servo motor turns, the rod magnet is pulled down about a half inch to an inch into the chamber, and this action causes the petal to fall. The servo motor returns to “slack” position and the spring returns the rod magnet back to its ready position.

The petals can then be reattached.

This drop mechanism is much more durable, and now that the magnets are “self-resetting”, I’m thinking of switching the slider-control based drop mechanism to a simple push-button interface.

(Update: I did so, and those changes are reflected in the Github code. It’s a simple four-button interface for the drop mechanism, one for each petal; this initiates a retraction of the servo, a pause for a second or so, and then restoration to the ready position.)

Epilogue

The performances— all eight showings — were smashing successes!

Izzy, the fifth-grade prop controller, did a great job controlling it and the prop functioned just as designed.

If there was a flaw, it was that one of the petal drops (of the 32) worked but got hung up on the LED light bush below it, so it appeared not to drop, but that was pretty minor and not a big deal.

Note that I did decide to replace the full set of AA batteries in the entire prop after the fourth performance. I can’t speak to whether that was unnecessarily premature, but there were no battery failures. Each performance was about 90 minutes, and the power to the prop was turned on about a half hour before and after each performance.

The Enchanted Rose Prop is now in the hands of the school theater director (and computer tech teacher; she’s one and the same) as a partial thank-you for all her great work with the kids.